How To Install Boat Windows

| |  |

Welcome to the UPDATED windows installation folio. Below is the installation on my modern catamaran but below that is the original didactics that has details you should also examine before taking on this chore.

| This is my Catamaran when getting a rig installed. The windows are 8mm or 5/16ths, Acrylic/ Perspex, supplied by Coastal Plastics of Tweed Heads NSW. That thickness has been quite adequate and we have been hit with seas against the windows hard plenty to set the boat over a meter in an instant. And so there is the nigh finished production. See the end of this section for more. |

| | I got some inexpensive, light plywood to brand templates of the windows. The large side windows are two sections with a gap in the middle to allow for exapnsion from the oestrus. I should have made that three sections. I screwed the panels into place to describe a line, then removed the panels and applied masking tape to comprehend the lines, then replaced the panel and drew the lines again but keeping about 6-8mm off the border. After that I removed the panel and used a sharp blade to cut along the lines. A medical Scalple or fresh box pocketknife bract. The panel shown in this photo is not the correct one and I do not recollect why it was used for this photo but the perspective is useful withal. The next photo will explicate. |

| | The templates yous see hither accept the window aperature cut out of them besides so the masking line can be acheived and the cut line for the aperature in your motel sides. The templates were sent to Coastal Plastics to apply for patterns. They transfered the shapes to their computer to plan their CNC router for the cutting. Be sure to make the plastic supplier aware there are left and right facing peices... as the outside edge should be slightly rounded. The round windows I didn't bother with patterns. I just gave Coastal Plastics the Bore I wanted and besides drew my own lines every bit well. I really like the roundies. |

| | The Plastic comes with paper roofing both sides. The inside of the window, I used the pattern to make a line just slightly inside, of the inside line and so cut forth that line. So peel away the paper. |

| Paint the inside part that you have exposed in the stride in a higher place. You lot don't need to encompass the surface with a thick coat. I used Septone brand high temerature paint with skillful event. When gear up to install, remove the paper totally from the outside. | |

| The aperatures have been carefully cut out with a Jig saw and painted. The tape is ready. Equally I had structures to stiffen the sides and there was no balsa invovled, I did not carp to reinforce the aperatures by decoreing and filling with glass. I accept an article about that on buildacat.com i left a generous 3 1/two inchs around the edges for the glue. The tape I used hither was 3M simply not the grey stuff, the VHB 4991. It meant more piece of work as the white stuff couldn't cope with the curve on the tips. | |

| Placing windows this size onto the tape and glued sections by mitt is impossible to do well. They are very hard to see merely I placed 2 screws on the underside of each window section. They are snug against the edge and the minor holes they created are covered with sealant when you remove them and fill the edge with sealant. | |

| I had to work fast on these big windows or I would have had more Photos! Straight sunday doesn't help either. Hither I have placed the rear section and am partway washed gluing the forrad section. When both were placed I shot sealant around the edges of both and imediately used my gloved and detergent lubed finger to course the edge. and then strip off the tape. I left about an inch between the two sections in the eye. | |

| Loftier stress work but the project goes fast. in a few hours you tin can have a de-stressing substance of your choice and admire the work. I was pleased with the result. In that location is more info beneath on materials used just I volition annotation here that I used Dow Corning 791 black, silicone. Fixtech also has a sealant they claim is acceptable for plastic windows, #200 | |

| This is more than than just an alibi to bear witness off my boat... though I practise think it is good looking... look at the windows on the side. They are covered with a cogitating tint. A mirror cease that reflects almost all heat from the sunday. This brings down cabin Temperture which is good in the torrid zone where I spend a lot of fourth dimension, and reduces expansion of the Acrylic to almost nothing, which farther insures the sealant'southward survival. If I get enough interest I volition get a page up with details of where, what and how. |

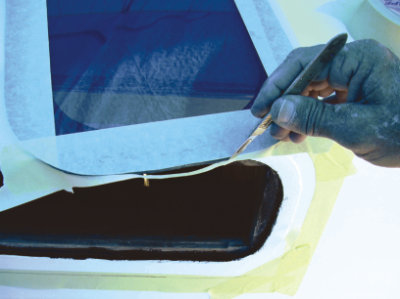

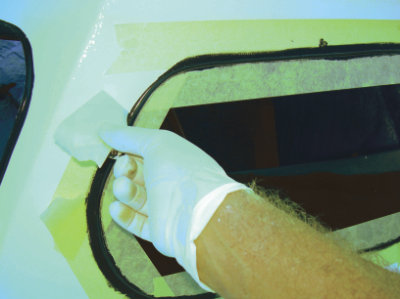

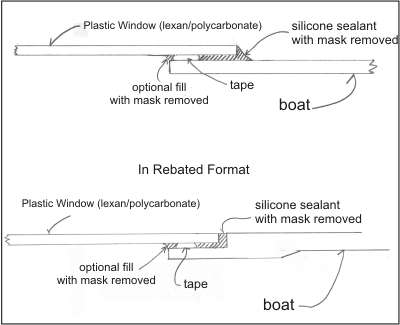

| Past Bob Norson When nosotros were rebuilding "WhiteBird" some years ago, I was told that new boats were beingness fabricated with windows/ports held in with two sided tape and silicone. I was replacing the old glass with polycarbonate but there was no way I was going to use wimpy shit like two sided tape to hold her together. In fact, in that location wasn't even enough screws left from the aluminium bezels to satisfy and so I went to work with drill and tap and bought boxes of 5 mil screws…. about 500 all up! When finished information technology was a piece of work of art and admired by all, zillions of shiny screw heads holding the dark tinted plastic against the neatly trimmed Black Sika Flex on sparkling white painted sole and combing. The only thing worse would have been a bunch of varnished teak!! I got away with it for a long time because I am always careful on boat work and fussy of cease simply something I've found near working on boats is this… PERFECTION IS But 90% EFFECTIVE! As well Sika Flex polyuerthane 291 not being upwardly to the claiming (not the all-time anyway) of sealing plastic with the expansion trend of "Lexan" (make name) or polycarbonate all those screws were an invitation to trouble. Some were bound to leak over time and they did. On a plastic boat that means yous have a tiny leak. On a steel gunkhole a tiny leak means y'all have a big problem eventually. As the water penetrates the sealant effectually the screw and begins to corrode the steel backside the plastic, the expanding rust scale wrecks the sealant confronting the plastic itself and … well you get the vicious circle idea. I had four things to do; first was to get the plastic. The supplier I used has ceased selling plastic so you are on your own to find a expert supplier. 2d was to repair the paint system, which on a steel gunkhole deserves a couple pages of it's ain. (Run across TCP # 27 for the commodity) Third was to find the correct sealant which wasn't as easy as you lot might call back only that is covered further along in this article. Lastly to mount the windows without screws and yet make it await sexy….. the dreaded two sided tape The window needs a relatively fifty-fifty surface. Besides the mechanical issues you lot don't want "waves" in your windows. If there is more than gentle curves involved utilise Wattyl brand fairing compound (recommended) between the primer and top coats somewhere to even things out. Information technology's a two part epoxy putty compound. Unless you let it go as well long the stuff sands fast and leaves a swell surface. The fairing doesn't need to extend beyond the area where the record volition be. If the sealant is a few mill thicker in one spot than another, no big deal. The sealant hides the difference well. All the paints and the fairing compound mentioned are products I have experience with and believe are the all-time for the task. For depression cost and expert advise I recomend Whitsunday Ocean Services in Airlie Embankment, email, telephone (07) 4948 1366. I have observed swell disparities in price on these materials. So.. nosotros all have an even surface to work from now, with a house substrate of paint or other durable, UV resistant surface. Ready STEADY GO!! Cut your plastic to size leaving a 40mm (1 ½") overlap (some say less merely I work on the "condom" side) for your tape and sealant. I used a metal cutting blade on a jig saw running at moderate speed with good result. A less than perfect cut can exist straightened out with a belt sander or file or whatever but don't polish the edge as you want silicone to stick to it later. Get out whatsoever plastic film in place on the plastic and note that Lexan has an "in and out" side. After cutting out I like to pigment the area that volition be the overlap facing in. Either use the plastic film that came with it or mask off with record. I used a medical scalpel for shaping the pic for masking. Xacto brand knives should work every bit well. Y'all tin become primers for plastic then coat with poly-U 400 but I found automotive exhaust pigment to be very tough and grippy on the shiny plastic. (This was an insider play a joke on I got from a lexan disributor!) The actual paint I used was "Septone" brand spray paint in a can. I recomend you test whatever paint y'all intend to use on a smal surface, allow dry and scrape and abraid to insure good adhesion to the plastic. Painting on the underside edges reduces UV that could go to the tape to degrade it and hides all the stuff so it doesn't look ugly. (Lexan brand polycarb is claimed to exist UV proof anyway.) Black was the colour advisable for my application. Adjacent…. The very important chore of masking off the sealant tin be washed now or afterwards. I chose early considering I wanted to utilise the window with some sealant goohed on the boat already. Some say that extra sealant isn't needed, they squirt it in afterwards the window is fastened with the record but I was worried most getting enough under the border, so I did it this way. I put masking tape on the boat and so held upwards the window and used a divider to mark off a line nigh 5mm over the size of the window. In one case marked I carefully (so as not to penetrate the paint surface) cut a line with my scalpel and lifted off the excess tape. At present strip off all the plastic film or masking tape you applied for the painting of the window and utilise a mask to the edge of the exterior of the new window to protect it from the sealant. I just laid it down quick and sloppy, then ran my blade effectually the edge and viola.. done. (see showtime picture) Next… 3M brand tape VHB 4991 is known to be very good. It comes in a coil, ½ inch wide by 100 feet (33metres) long and two.3 mm thick! Make sure you become the correct stuff. Call 3M for more information, 136-136. This record is used in the automotive industry to hold those plastic panels in place on the side of many newer cars (this info may assistance you find a supply). I used two strips of ½ inch to make the recommended i inch total (note that I accept revised the recomendation of the 1 inch width of tape back to just i/two inch). Apply the record to the gunkhole toward the inside of the 40mm overlap area. Next……At present strip off the cover on the two-sided tape and optionally (every bit I chose), squirt on a line of silicone nether where the edge of the window will be, but not too close to the exposed record surface. When the window is applied yous don't want the silicone to invade the tape. Raise up your prepared window and advisedly…..oh so carefully... put the window in place. You just take one shot at this. If it's incorrect you are screwed, blued, stuffed and tattooed. Don't think you can move and slide, you can't. Information technology's either right or become out the hammer and chisel. Assuming its right, use your palm to push button hard to really set the tape to plastic. Now that you are considering that stress, lets talk silicone! The right stuff is hard to find. You need a silicone of the correct colour (black in my case) with a neutral cure. If using Perspex you may get abroad with only a twenty% + or- joint movement capability. With lexan or polycarbonate y'all need more because it's rate of expansion is greater. I plant the right stuff at "Lincoln Sentry" in Mackay. Information technology is Dow Corning brand, silicone # 791 with a whopping motion charge per unit of 50%!. The Dow material is intended for the construction industry. Those glass and steel role buildings use very large panels of glass. Considering of the size of the drinking glass, they tin aggrandize a lot and this silicone is intended to tolerate that. 3M also has a sealant intended for apply with Lexan, consult your local dealer. Normal polyurethane sealant is not up to the job. Your Sikaflex 291 may hold for a while just sooner or after the expansion of the polycarbonate will overcome the adhesion and it volition start leaking. A very thick bedding of the sealant will boring information technology downwardly though. Next…. If you haven't already, mask off the outside at present. (virtually 5-6mm from the edge of the plastic on a apartment surface or to the edge of a rebated surface) Squirt a line of the silicone all the fashion around the outside edge. With a rubber glove covered finger, work the silicone into and under the edge of the plastic and finally smooth off the whole way round. Don't leave whatsoever holes or crude spots. Now carefully pull off the record. Don't wait till it starts to set. Get all the masking off at present. The silicone will skin out in a couple hours simply you should give the project 72 hours earlier you abuse it. Rubber gloves are inexpensive at the supermarket so use plenty of em. Go along a bottle of methylated spirits and paper towels handy to wipe upwardly the stray accidents. Washed!I cheers to: |

Source: https://www.thecoastalpassage.com/windows.html

Posted by: luftacte1966.blogspot.com

0 Response to "How To Install Boat Windows"

Post a Comment